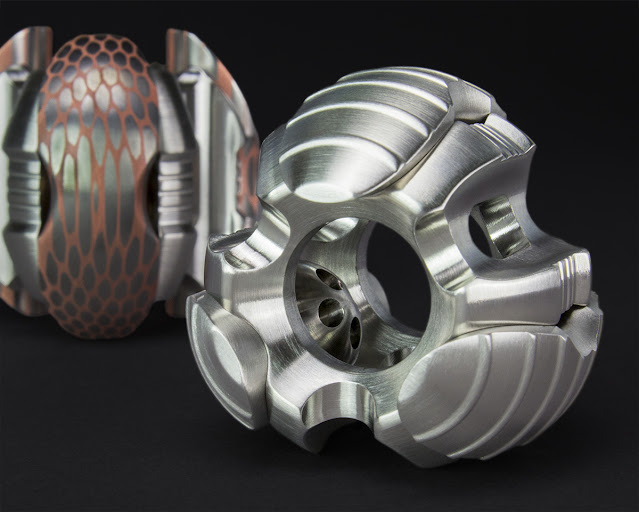

Introducing the TKS, The second in a series of magnetically modular mini sculptures. Everyone knows I love iterating around an idea and my last small magnetic work was ripe to expand upon.

The first of the series was

the NC3. When working on that piece I wrote about the novelty (and perils) of using magnets. I said that I am cautious when using materials that are inherently novel because novelty itself can become the dominant medium, one with a short shelf-life.

While I am always careful about how I employ mechanics to ensure I am pursuing sculptural ends, it is easy to become dogmatic to ones detriment, and it occurs to me that in order to truly understand something (like novelty) it helps to lean into it on occasion.

So with that said let's dive into what's behind this new piece.

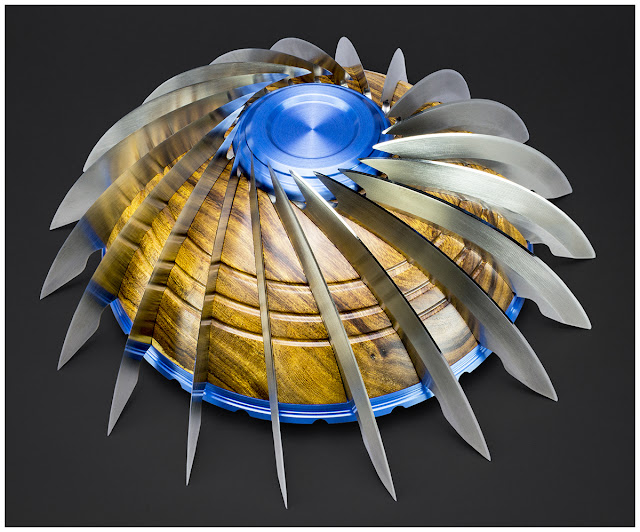

In addition to magnets, I have added some ball-bearings to the configuration, because if I am going to explore mechanical novelty, well, it ought to have layers.

This results in a magnetically modular piece that not only spins, but also has a remarkable tactile feeling when rolled around in the hand. This piece is as much a joy to hold as it is to look at.

There is more to why I find this work so interesting, so lets keep going.

Another topic that arose while working on the NC-3, the work that preceded this, is that it was based on well-defined geometric principles. The NC-3 was built around a platonic solid called a octahedron. This new work is built on another platonic solid, the tetrahedron.

While practicing machine work requires good working knowledge of various geometric principals, I have never really considered what I do to be “math art”. If you dig around a bit, you will find that math art is quite its own thing (see my sculptor pal

George Hart). Math art is not really something I can lay any real claim to (for lack of true mastery) but my work often overlaps with it at the edges and this is a case where I wanted to push into that sphere, if just a little. And so I quite intentionally adopted the tetrahedral format as my starting point rather than just being a convenient coincidence.

The frame work for the entire piece was built around something called the "dihedral angle" which is the angle between the faces of a given shape. The dihedral angle of a tetrahedron is 70.529° and it is an important angle because it is used to ensure all of the magnets sit face to face when assembled.

The rest of the visual form was derived from using that angle as a constraint.

In addition to basic geometry, this work had a number of more technical engineering challenges that proved a great opportunity to apply some fascinating physics principles.

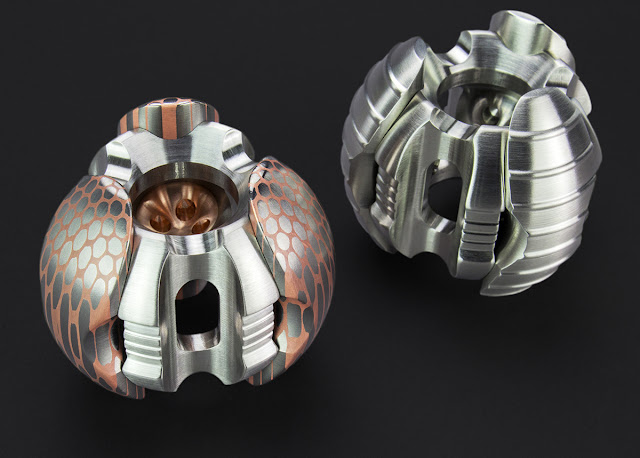

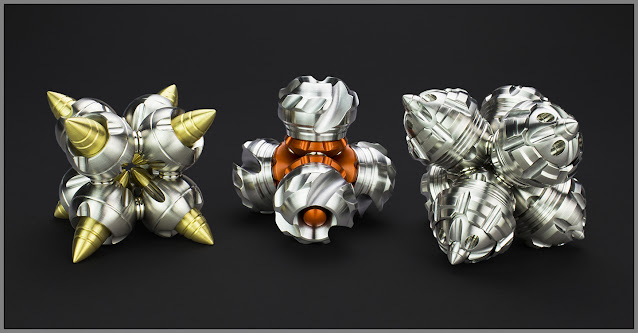

For starters, unlike a octahedron, mating the parts of a tetrahedron with magnets does not present a straightforward solution in terms of arranging the polarity across them. Getting four individual pieces to attract the other three meant that I couldn’t simply apply a single polarity (north, or south) to each part evenly. Instead I ended up with a polarity map like the one you see above.

The result is that while the NC-3 was fully rearrangeable, this work really only assembles one or two ways.

Getting the magnetic assembly solved was just the beginning however. Making the rest of the mechanics play nicely meant finding a sweet spot between the mass of the parts and the magnetic forces employed to hold them together.

My first prototype for this sculpture had two main issues. The mass of the stainless steel spinning elements was a bit on the heavy side, and the magnetic pull holding them together was a bit on the weak side. This meant that the centrifugal force of spinning the sculpture was prone to sending those stainless elements flying off.

To make the parts lighter without wildly altering the piece, I applied what is known as the

square cube law, which states that an object's volume increases (or decreases) at a greater rate than its surface area when being scaled.

A simple example is that a 1" cube has a surface area of six square inches and a volume of one cubic inch. If you double its size to a 2" cube, the surface area increases to twenty-four square inches (a factor of 4 or 22). However the volume of that same cube increases to eight cubic inches, (a factor of 8 or 23)

Practically applied, by decreasing the overall size of the parts by a mere 3%, I was able to make the entire work a full 10% lighter (I also fiddled with some internal dimensions to squeeze that extra 1%).

To increase the magnetic attraction between the parts, I had to move the magnets closer to their target. How much closer would make a difference? It turns out a very small amount, and the

inverse square law is how to explain this.

The force of attraction between two magnetic poles is inversely proportional to the square of the distance between them. In this instance I was solving for magnet to steel, but the principal is the same.

After crunching the numbers, I calculated that I could increase the magnetic force by a factor of 2.6 simply by moving the magnets a mere .016” closer to the parts I wanted to stick.

This small design change was trickier than it seems, but it made an enormous difference. Now the parts all attach quite securely.

This is all pretty basic stuff to an engineer, but I still find it immensely satisfying to be able to ground elements of my work in some real nuts-and-bolts logic. In the video above I discuss all of this a bit more casually. A video is worth a million words however, so hopefully it helps smooth out all the "umms" and "ahhhs"that come out of my mouth.

Another fun thing is that since these pieces contain magnets they sort of talk to each other when moved in proximity.

I am pleased with how many interests of mine I was able to wrap into this little work. I hope it helps demonstrate how pursuing machine-work as a visual medium constantly brings one into contact with other spheres of knowledge.

I have never had to look far to find a catalyst for a visual concept and this piece embodies this idea nicely. Who knows, maybe this will end up being a three piece set.

|

| Simulated color pallet for the edition |

So as is customary, I am going to offer these up as an edition.

I am adding pink and yellow to my anodizing line so there will be lots to choose from in terms of colors.

I will post a sign-up starting Friday April 16th at 10 AM EST. I will include details of the sale as well as the price at that time.

As always, comments and questions are welcome.