Well, the year is coming to a close and my shop is a mess, time for a good cleaning and then a break, but first things first. I just put the finishing touches on this beauty and I couldn't be more pleased with my final effort this year. I always try to be ambitious towards years end and this year was no exception.

12/13/11

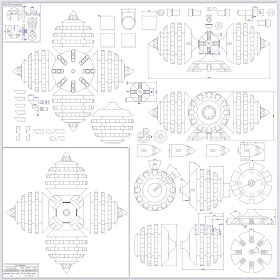

Final work and news of 2011

Well, the year is coming to a close and my shop is a mess, time for a good cleaning and then a break, but first things first. I just put the finishing touches on this beauty and I couldn't be more pleased with my final effort this year. I always try to be ambitious towards years end and this year was no exception.

12/1/11

A New Edition

Thought I would post my newest work. I made three of these little gems and they are directly related to some of the geometry I am using in my current large project (to be completed by the end of the year).

10/6/11

Triplet

A commission leads to an interesting pair of works.

These are my latest creations ( There are three here). The pair you see above are a variant on the one here just below. The one below was a commission for a collector who liked my TI 524422363 so much he wanted me to dream up something with a similar organic, yet vortex-ish flavor.

7/21/11

TI 524422363

Every once in a while, I get myself into making something and it just seem sthat everything that can go wrong, will and is going wrong. But when I press on through it, the product at the other end is a wonderful mixture of good intentions and adjusting to the circumstances at hand. This piece in particular exemplifies the term, happy accidents.

Tr 334425524622211

My latest creation everyone. This one took some time, but it was well worth it.

It stands about 19 inches tall and is about 8 in diameter.

6/26/11

Coming Soon!

6/11/11

New small works

These two are the second and third

installments before I move on to a bigger project. This first one is more a

technical achievement than anything.

The machining of the center piece on this one involved writing a program

that wrapped a helix around the sphere. rather than run the cut straight

through It took quite a while to figure out the tool path geometry because

it involved changing the helix as the cutter progressed deeper into the work

piece. Not an easy thing for me to solve. Also making the actual cuts in

Stainless steel called for some extra care as well.

5/18/11

CL863624433722235525, a new work and Some good news

So I have been out of the shop for a number of weeks. My show in New York, combined with a number of other obligations and unexpected distractions has slowed me down and cost me a few weeks in the shop. But I finally managed to steel away some time and make this little fellow to get things moving again.

4/18/11

SOFA NY 2011

Here is an image from my booth at SOFA New York (ignore the chairs). It was a great show and I met a bunch of interesting people, but boy am I tired and glad to be back home. Its good to make an effort to get your work out there and most of the time, I have to force my self to. Otherwise my natural instinct would be to work in the shop all the time and never go out. So this accomplished that task nicely. But now the show is over and its time to start some new projects. So look for new work in a few short weeks.

4/9/11

Chris Bathgate Solo Show with Packer Schopf Gallery @ SOFA NY

(Booth#311) @SOFA NYC, Park Ave Armory, Park Ave @67th St., NYC, Event Dates, April 13 - 17

www.sofaexpo.com

Show Dates

SOFA VIP Reception: Wednesday, 5 – 9 PM, April 13, 5PM – 9PM(tickets must be purchased)

SOFA General Show Hours

Thursday, April 14, 11AM – 7PM, Friday, April 15, 11AM – 6PM

Saturday, April 16, 11AM – 7PM, Sunday, April 17, Noon – 6PM

www.sofaexpo.com

Show Dates

SOFA VIP Reception: Wednesday, 5 – 9 PM, April 13, 5PM – 9PM(tickets must be purchased)

SOFA General Show Hours

Thursday, April 14, 11AM – 7PM, Friday, April 15, 11AM – 6PM

Saturday, April 16, 11AM – 7PM, Sunday, April 17, Noon – 6PM

3/30/11

An Experiment in Scaling

Here are the images for what I am going to consider a trip-tic. I already posted about the last edition, but I was kind of taken with the proportions of that design and I wanted to explore them further with a more ambitious work. My first instinct was to make a larger version and expand on the concept and see where it lead me, But while I was at it, I figured I could go the opposite direction as well. So in short, I made a small set of 1/2 scale works along with a Larger "one of a kind" that is 2.3 times as large as the original. Both with design changes that I found appropriate for the different scales.

The Small Version

The 1/2 scale version is quite similar to the original with some simplification of the design to account for scale. But this one was a much more of a process oriented experiment. I took this redesign as an opportunity to play with some process elements that I rarely ever have the opportunity to think about.

When making one of a kind works and short run objects, you rarely get to play with optimizing your processes to make them more efficient and more elegant. Designing a program and its associated set ups and operations to cut a shape can be done many ways, But when you get a second chance to simplify an object, you get to indulge in taking the time to streamline the programs and improve on the different operations based on what you learned doing it the first time. So yeah it was kind of a chance to nerd out on my craft a bit, but I got a lot out of it and now I have a bunch of these little guys to offer. I was able to shorten the production time significantly.

The Large Version

2/28/11

ST 732232835563624434

This one was a six week slog and involved lots and lots of hours of hand sanding and achy fingers but I m quite happy with the result.

As it is now it is actually sitting on my desk, although I am still deciding whether to actually make this thing a wall mounted work. I do not usually go that direction, but this one seems like it would benefit from that kind of mount, as it is the only way to really take it all in at once. I'm going to give it a little time before I decide.

As it is now it is actually sitting on my desk, although I am still deciding whether to actually make this thing a wall mounted work. I do not usually go that direction, but this one seems like it would benefit from that kind of mount, as it is the only way to really take it all in at once. I'm going to give it a little time before I decide.

1/29/11

Current Project

So these are rather large blanks I am starting with. They are 6" Diameter rounds and holding them on some of my tools is a tricky prospect so I started by machining both a clamping lip onto it and drilling and tapping holes so I could bolt it directly to a faceplate for turning.

This part of the work will eventually be machined off so there is no harm done to the actual part

This part of the work will eventually be machined off so there is no harm done to the actual part

1/19/11

PN635512223333

This will be the third small edition I have made so far and I must say, If I was hesitant about making editions at first, I am not anymore. They are extremely satisfying to make and there is something about seeing your work in multiples that is very pleasurable, Not to mention how it changes the pacing of actually making a particular design.

This one was a bit more ambitious than the first two editions as far as size and time investment. The center piece is Bronze with Stainless steel ends. The inserts are aluminum and copper and the whole thing sits on a Stainless base.

The starting point for this work was kind of a revisiting of a very early design element I used many years ago while I was still working out the visual language of these objects. At the time I had a good "hook" (for lack of a better term), but not the proper experience yet to execute it in an elegant manner such as this. Which is not to say the original piece isn't important, just that there is nothing wrong with taking a second swing at something good and ending up with a different result.

1/18/11

Work Featured in Make Magazine

My work has just recently been featured in Make Magazine and I thought I would send out a link to everyone. Its not exactly a fine arts publication, but it is certainly one that I thoroughly enjoy reading.

For those not familiar with the magazine, in their words it is

"The first magazine devoted entirely to DIY technology projects, MAKE Magazine unites, inspires and informs a growing community of resourceful people who undertake amazing projects in their backyards, basements, and garages. Coined Martha Stewart For Geeks by Newsweek's Stephen Levy, MAKE is one of the most highly regarded and well-published success stories in the consumer magazine space over the past year."

It has been on newsstands for just over a week, but I wanted to wait until the electronic version was up and running so I could provide a link.

Chris Bathgate in Make